Initial situation

During the solidification process of metal melts, complex chemical-physical processes occur.

Despite the separation of the raw materials required for the production of castings, the composition of the starting materials, secondary or primary raw materials is often not sufficiently known.

Other variables such as temperature differences between start and end of casting, weekend holding times, too much or too little inoculation or other errors in the process influence the solidification process and thus affect the quality of the castings.

In order to optimize the result of the casting process, the control of the chemical composition of the molten metal as well as the monitoring of the inoculant content and the different phases of the solidification are necessary.

Quality assurance through the use of the thermal analysis package apromaceTA

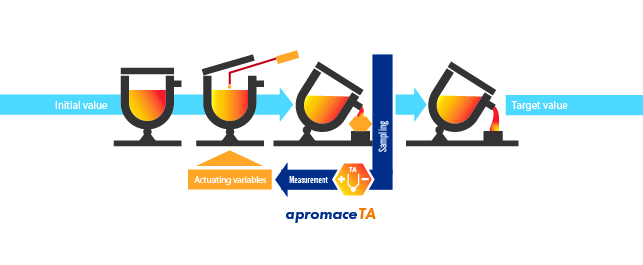

The thermal analysis provides information on the metallurgical behavior of molten metal.As a method for determining the characteristic points (POI) during the phase transformations from the cooling or heating curves of a melt, the thermal analysis serves as a control element of the process control in foundries.

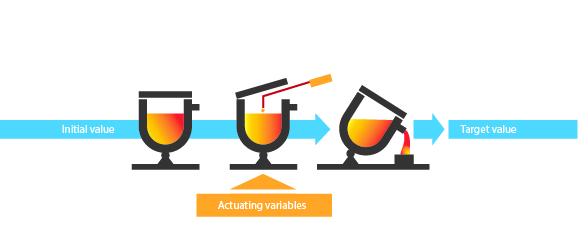

With the apromaceTA thermal analysis package, quality-relevant parameters are recorded and evaluated during production, so that it is possible to influence the metallurgical state of liquid metals in a timely manner in which deviations are diagnosed and corrected by controlling the proportion of the melting components